Sustainability

Environmental Protection Commitment

-

- 2023.05.31

- 【Jiangsu CT Qingjiang honored as a green benchmark enterprise at the municipal level】

As one of the key member companies of the Group, CT Qingjiang continued to promote green transformation and has built a scientific, environmentally- friendly, energy-saving, clean and civilized enterprise in recent years by continuously optimizing its industrial structure in accordance with the national industrial policy. In October 2022, Jiangsu CT Qingjiang was awarded as the one of the first batch of green benchmark enterprises in Huai’an City and “the most beautiful factory” in Qingjiangpu District of Huai’an City.

-

- 2023.05.31

- 【Photovoltaic power generation project of Sino Biopharmaceutical】

Sino Biopharmaceutical actively promotes the application of renewable energy, vigorously expands the use of photovoltaic power generation to replace traditional energy and reduces GHG emissions. Among them, the photovoltaic power generation project of the production plant of CT Tianqing in Haizhou completed the construction of Phases I and II of photovoltaic construction and started grid-connected power generation in 2021, with a total installed capacity of 2.1MW and a power generation capacity of 2.965 million KWh in 2022; the photovoltaic power generation project of the production plant of CT Tianqing in Shunxin officially started operation in October 2022, with a total installed capacity of 0.8MW; the production plant of CT Tianqing Runzhong in Lingang used its 7,500-square meter carpark to build its photovoltaic carport, which was completed at the end of 2022 and can realize an annual power generation capacity of about 1.5 million KWh.

-

-

- 2022.12.31

- 【Environmental compliance audit】

In 2022, the Group carried out environmental compliance audit, covering all key member enterprises of the Group. The audit content includes the collection and disposal of three wastes (solid waste, liquid waste and gas waste) and the storage and management of hazardous chemicals. According to the audit results, relevant enterprises have completed the corresponding system management process rectification and equipment update; The renovation project of the organized emission of waste gas from manufacturers of raw material drugs are in progress or have been rectified.

-

- 2022.06.30

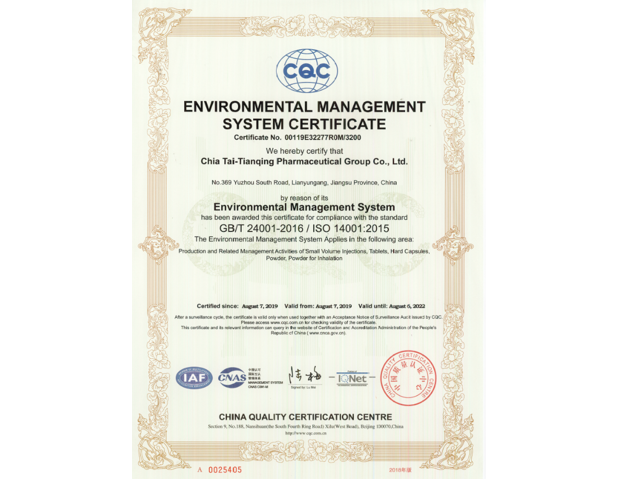

- 【Environmental management system certification】

As required by Group policy, a member company of Sino Biopharmaceutical regularly carries out ISO14001 environmental management system certification, receives China Quality Certification Center (CQC) re-certification audit every 3 years, and receives CQC supervision and audit every year during the validity period, to ensure the continuous compliance and effectiveness of the environmental management system.

-

-

- 2022.06.30

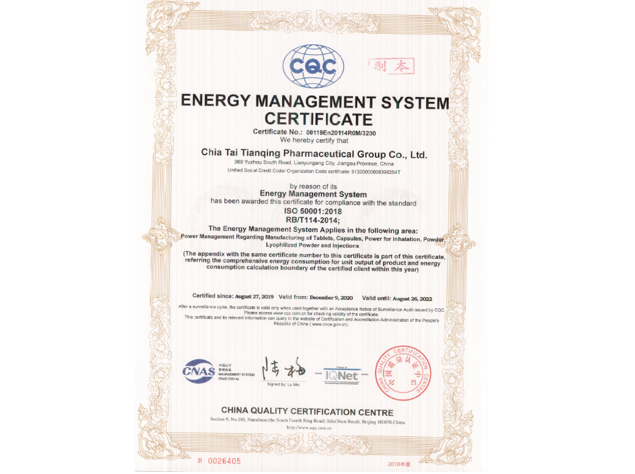

- 【Energy management system certification】

As required by Group policy, a member company of Sino Biopharmaceutical regularly carries out ISO14001 energy management system certification, receives China Quality Certification Center (CQC) re-certification audit every 3 years, and receives CQC supervision and audit every year during the validity period, to ensure the continuous compliance and effectiveness of the energy management system.

-

-

- 2022.01.01

- 【Hazardous Waste Emission Reduction】

The Group is committed to reducing hazardous waste generated in the process of production and operation. In 2021, member companies continued to improve the hazardous waste management mechanism and took various measures to reduce hazardous waste in the production and operation process, including reducing the amount of cleaning waste liquid by improving the utilization rate of equipment and reducing the production batch, introducing advanced sludge drying equipment to reduce the amount of sludge, optimize the process and refined management of raw and auxiliary materials to reduce hazardous waste at source.

For example, in the production process of rivaroxaban, Nanjing Chia Tai Tianqing uses low-toxic reagents to replace the reagents with high toxicity and strong volatility, and optimizes the reaction temperature parameters to reduce the volatilization of solvents, and uses inorganic alkali instead of organic alkali to reduce the production of organic waste liquid. At the same time, the amount of chemical reagents and catalysts were optimized to ensure the quality and reduce the use of reagents.